Hemp makes a comeback in the construction industry

Weary of his life as a computer engineer, in 2010 Elad Kaspin packed his bags and travelled the world.

Mr Kaspin wanted a break from Israel, describing life in the country as complicated. “I knew I didn’t want to live there, in spite of having a good life with a good salary,” he says.

After two years of travelling, he arrived in Colos, a village in southern Portugal, between the towns of Odemira and Ourique. He liked it so much he decided to stay.

He was not the only one. In recent years the region has seen a wave of migrants, attracted by the dramatic, vast and empty plains, a laidback way of life, good weather, and cheap property.

But that popularity was not generating good, stable jobs.

So, with the help of childhood friend Palestinian Omer ben Zvi, Mr Kaspin decided to start a company, Cânhamor.

Their idea was to take advantage of Portugal’s relaxation of laws governing the cultivation of hemp, part of the cannabis family of plants.

With official permits, the cultivation of cannabis and hemp has been permitted since 2018.

The laws have been refined since then, but with authorisation from the General Directorate of Food and Veterinary Affairs, farmers can grow hemp as long as there is oversight from regulators.

It marks a revival for hemp in Portugal. It was an essential raw material for the nation’s maritime expansion, which began in the 15th Century, when it was used to make cords, ropes and sails.

Hemp fibre was prized for its durability, a quality which has caught the attention of today’s construction industry.

Not only is it tough, but hemp also has the potential to make big savings in carbon dioxide emissions.

The plant traps carbon dioxide when cultivated and can, when made into blocks, replace concrete, which is a carbon-intensive product.

According to a European Commission report, the carbon sequestering properties of hemp are remarkable.

In just five months one hectare (2.5 acres) of hemp can trap between 9 and 15 tonnes of carbon dioxide.

Mr Kaspin wanted to exploit those properties by setting up his own business making hemp construction blocks.

With an initial investment of €1m (£880,000; $1m), Cânhamor was formed at the beginning of 2021, and production began a few months later.

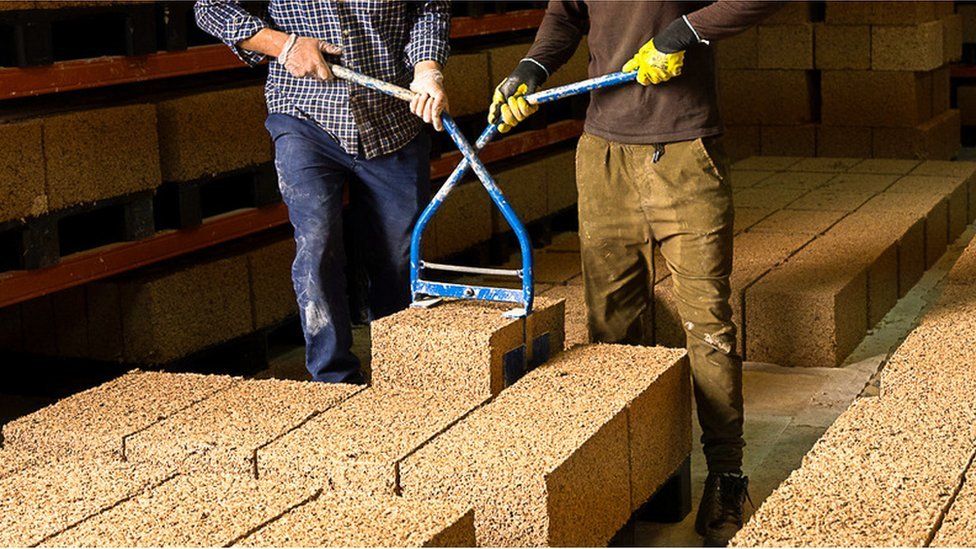

The blocks are made of so-called hempcrete, a mix of hemp plant parts, water and limestone powder.

According to Mr Kaspin, the blocks have several advantages over traditional building materials.

As well as being much less carbon intensive to make, he says hemp blocks are better at insulating from heat and sound than brick and concrete.

He also says that they are very resistant to fire.

In 2019 researchers in Australia conducted tests on hemp walls, including simulating a bush fire, and found the material very resistant to fire damage.

However, hemp blocks have to compete with concrete which is cheaper, stronger and well known to builders.

The cost of hemp blocks also reflects the cost of growing hemp which includes expensive inputs like fertiliser.

In the early days, Mr Kaspin struggled to convert customers to hemp blocks.

“The construction sector is a very conservative sector with almost non-existent changes. Many architects and builders do what they have always done. It is not easy to introduce new things,” he says.

But after several trials, they found some customers and have been building up the business ever since.

Currently Cânhamor produces between 4,000 and 10,000 blocks every month, enough to build about three houses.

Demand is strong and the company has a new factory planned, which should produce about 120,000 blocks a month.

So the next problem is sourcing enough hemp to feed the new factory.

At the moment Cânhamor buys hemp from abroad which pushes up the cost of its blocks. The plan is to persuade more local farmers to cultivate the plant.

“There was no factory because there was no cultivation, and there was no cultivation because there was no factory. We have the opportunity and the privilege to break this cycle,” Mr Kaspin says.

“With local materials, and with larger capacity, production costs will drop significantly. In 2024 we will be able to offer our blocks at much lower prices,” he predicts. “Even cheaper than concrete.”

To produce enough hemp fibre, he estimates that 1,000 hectares of hemp will need to be cultivated.

“We are in talks with several farmers. We offered to buy their whole crop. And we know that there are people who want to buy not only blocks, but every hemp by-product that we will make in the new factory.”

They will start tests in January with a handful of experienced local farmers, planting hemp in a cultivation area of up to 10 hectares, “so they can try and see,” says Mr Kaspin.

He expects to be able to tap up to 150 hectares of local hemp production by the end of this year. For 2024, the target is 500 hectares. But it will depend on Alentejo’s farmers’ willingness to change tack towards the leafy plant.

Cânhamor will have to compete with larger European companies such as Belgium’s Isohemp.

Its factory, located in central Belgium, has a production capacity of five million blocks per year, or enough to build around two houses a day.

Unlike Cânhamor, it can source most of the hemp it needs locally, from the north of France and the south of the Netherlands.

But the two firms do share one similar challenge.

“The construction sector is indeed a very traditional market and habits take time to change. The current obstacles are the lack of knowledge of the product,” says Charlotte De Bellefroid from Isohemp.

Back in southern Portugal, Cânhamor is set to become one of the biggest local employers, raising its number of workers to 30, up from the current six who work on the production line.

Marcelo Guerreiro, Ourique’s Mayor, tells the BBC: “We weren’t acquainted with hemp’s potential but we dealt with the proposal with an open mind.”

The local council gave Cânhamor the land it needs for the new factory. Cânhamor has raised the money needed to build the factory, estimated at €5m.

“Thirty jobs is very significant for Ourique and Cânhamor will become one of the biggest employers of the town,” the mayor says.

“We are satisfied with the recent evolution concerning cannabis in Portugal, not only in legislative terms but in terms of society acceptance,” he adds.