The race to make diesel engines run on hydrogen

It’s a new hydrogen-diesel hybrid engine affectionately known as “baby number two” that could help to decarbonise some of Australia’s heaviest industries.

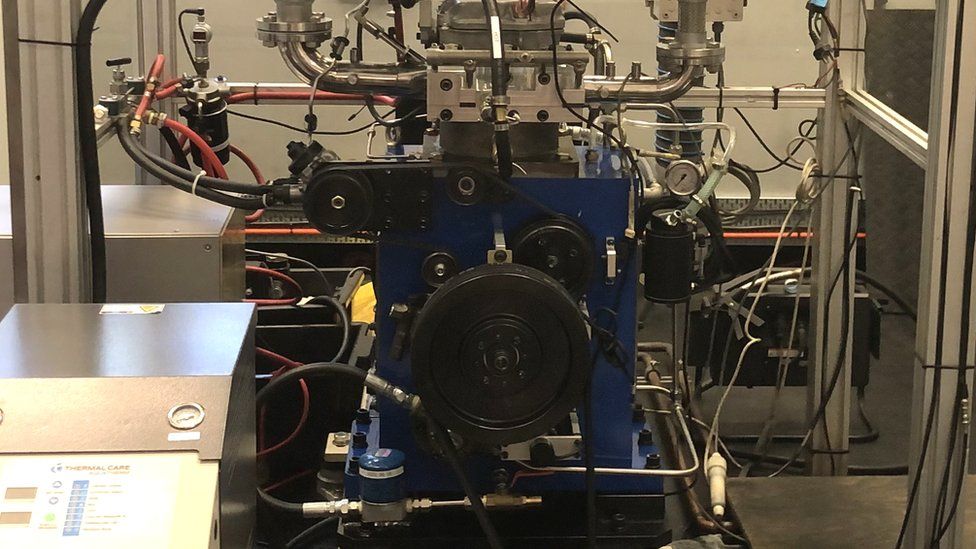

The test rig is large – it has its own room adjoining a lab and looks at first glance like many other large motors, but beneath its metallic skin could lie game-changing technology.

Engineers at the University of New South Wales (UNSW) say they have successfully modified a conventional diesel engine to use a mix of hydrogen and a small amount of diesel, claiming their patented technology has cut carbon dioxide (CO2) emissions by more than 85%.

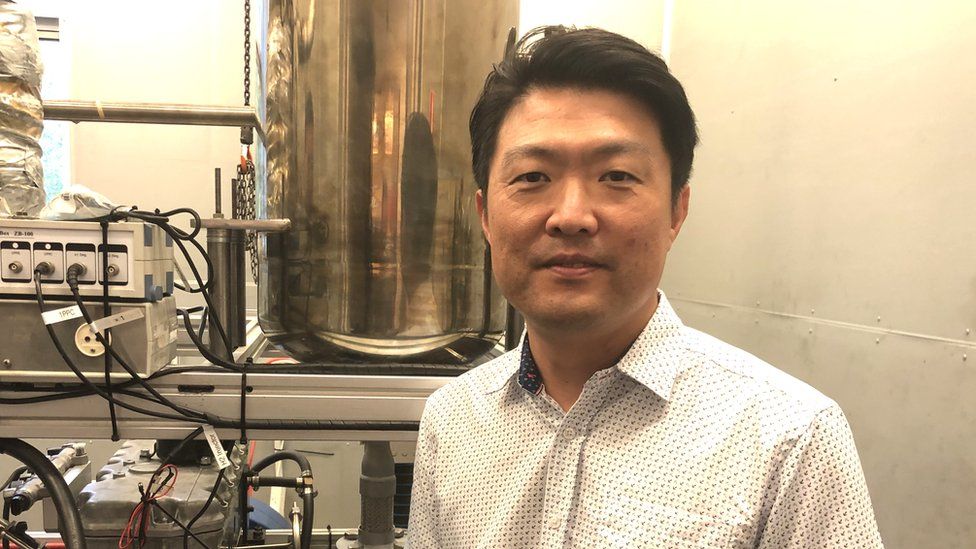

It’s the work of Prof Shawn Kook and his team at the university’s School of Mechanical and Manufacturing Engineering.

“The interest in converting an existing diesel engine into a clean-burning hydrogen engine is extremely high,” Prof Kook tells the BBC at his laboratory in Sydney. Enquiries have come from Germany, South Africa, Brazil, Japan and China.

“We mount the hydrogen direct injection system into existing diesel engines, which can be applied to any conventional engine,” he adds.

What makes their system unique, according to Prof Kook, is the way it mixes the hydrogen and diesel and then introduces it to the engine cylinder for combustion.

Unlike fossil fuels, hydrogen does not produce CO2 when burnt, so it has long been seen as a greener fuel source.

About 90% of fuel in the UNSW hybrid diesel engine is hydrogen but it must be applied in a carefully calibrated way.

If the hydrogen is not introduced into the fuel mix at the right moment “it will create something that is explosive that will burn out the whole system,” Prof Kook explains.

He says that studies have shown that controlling the mixture of hydrogen and air inside the cylinder of the engine can help negate harmful nitrogen oxide emissions, which have been an obstacle to the commercialisation of hydrogen motors.

The Sydney research team believes that any diesel trucks and power equipment in the mining, transportation and agriculture sectors could be retrofitted with the new hybrid system in just a couple of months.

Prof Kook doubts the hybrid would be of much interest in the car industry though, where electric and hybrid vehicles are already advanced and replacing diesel cars.

However, he says Australia’s multibillion-dollar mining industry needs a solution for all its diesel-powered equipment as soon as possible.

“We have so many established diesel-powered generators, mega-trucks and underground machines. How do we decarbonise all those existing diesel engines? One way is to shut down everything and get new technology in, which will take decades,” he says.

The plan is for the hybrid to run off a hydrogen-diesel mix or, in the absence of hydrogen, it can revert to diesel only.

Prof Kook hopes his new generation engine will become a commercial product within two years.

Tim Buckley, the director at Climate Energy Finance, a public interest think-tank in Sydney, believes the technology has the potential to “transform the Australian mining industry dramatically”.

“There’s always an element of scepticism in the work I do to evaluate what is hype and hope as opposed to reality. Having said that, this University of New South Wales breakthrough does appear to be pretty material. If they can pull it off it is a huge opportunity,” he says.

The Australian team is in a global race to develop hybrid diesel-hydrogen engines. Engineers in other countries are working on their concepts and designs but the Sydney team believes it has an edge.

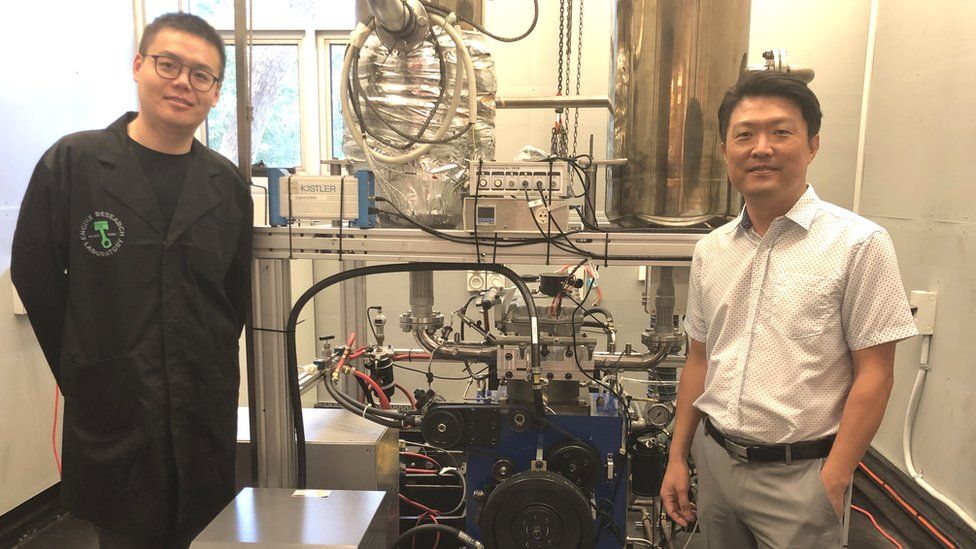

“I think we have a breakthrough compared to most other research groups in the world where we can actually achieve a higher percentage using hydrogen over diesel,” explains Xinyu Liu, a UNSW PhD student from China.

“Emission-wise, CO2-wise we can achieve a higher reduction than the other methods. The concept has been proven using the previous small-scale engine. We are trying to implement this idea into a larger scale, which is more [applicable] to industry.”

The bigger version, or the UNSW’s “baby number two”, has twice the volume of the original prototype and has the potential for a “massive reduction in CO2” emissions, according to Prof Kook.

The vision is laid out in a paper published in the International Journal of Hydrogen Energy.

Much of the invention’s impact on the environment will depend on where the hydrogen comes from.

While small amounts of hydrogen are being extracted directly from the ground, most hydrogen is manufactured, in a process that emits CO2.

Green hydrogen, produced by using electricity from renewable power to split water into hydrogen and oxygen molecules using an electrolyser, is seen as the answer. But the technology and the electricity needed is costly, so at the moment only a small amount of hydrogen is produced this way.

But the costs are likely to come down and with abundant sunshine and wind, Australia has a lot of potential to produce renewable electricity, which could one day be used to make more green hydrogen.

The Climate Council, an independent organisation, believes that sustainable hydrogen gives Australia the chance to end its reliance on fossil fuels.

“Australia is one of the world’s largest coal exporters and the largest liquefied gas exporter,” the Council wrote in a 2021 briefing. “Both are polluting fossil fuels, and Australia is paying a high cost for that with more severe and frequent extreme weather events like bushfires, heatwaves, and drought.”

For now, the UNSW project remains in the nursery in the laboratory. Academic endeavour needs the financial heft of outside investment and the hands-on input and knowledge of a mining company or engine manufacturer.

“Our vision is to impact Australian mining, agriculture and construction industries first and then move out to the rest of the world to make a bigger impact,” says Prof Kook.

Australia has some of the world’s biggest resources companies and they have all committed to aggressive decarbonisation targets. Technology is the key.

“The idea of blending hydrogen and diesel together in an existing engine is something of a Holy Grail for decarbonising heavy industry and mining,” adds Tim Buckley.

He has this existential question for the engineers at UNSW: “Can they actually deploy it in a commercial setting and replicate it outside the university?”